Written by Brian Wahlin, Ph.D., P.E., D. WRE | WEST Consultants

Copyright © RASModel.com. 2011. All rights reserved.

In modeling irrigation canals in HEC-RAS, a typical structure that is encountered is a check gate. Check gates are designed to back the water up behind them in an effort to keep the water level immediately upstream of these gates at a constant level. As the flow rates change in the canal, the gate openings on the check gates are adjusted (i.e. opened or closed) in order to pass the new flow rate while maintaining the water level upstream of the check at the desired elevation. Why go through this effort? Farmers usually get their water from these irrigation canals via orifices just upstream of the check gates. The flow through these orifices is dependent on the head (or the water surface elevation) acting on it. Since farmers want a constant flow rate delivered to their fields, the check gates in the main canal are adjusted when the flow changes to make sure the water level upstream of the check (and hence the rate of flow delivered to the farmers) remains constant.

Check gates can take a wide variety of forms, but typically they fall into two categories: undershot gates and overshot gates. Undershot gates are things like radial gates and sluice gates. As the name implies, water shoots “under” these gates. Inline weirs are typical examples of overshot gates. For these structures, water does not pass “under” the gate but instead flows over the top of the structure. Since many irrigation districts operate on limited budgets, it’s not uncommon to see an overshot gate made simply of several 2x4 wood boards that slide into groves in the canal walls. The irrigation canal operator “opens” these types of gates by manually removing one or more of the wood boards. In a similar manner, these gates are “closed” by adding one or more wood boards.

Modeling undershot gates has been straightforward in HEC-RAS for many years. You simply select whether you have a radial gate or a sluice gate and then enter the appropriate input data for the gate. The gate openings are then set through the flow editor-either steady state or unsteady state-depending on your situation.

Modeling overshot gates in HEC-RAS has been a little more challenging. Unlike the undershot gates, there really wasn’t a gate type that allowed water to flow over the top like a weir. Thus, you had to model overshot check gates using the geometry of the inline structure. An example is shown in the figure below. The four long white rectangles in the middle of the structure are undershot types of gates (in this particular case, they happened to be sluice gates). The two short white rectangles at the far right and the two at the far left (the ones with the open top) are overshot gates. Because in previous version of HEC-RAS, there wasn’t a particular “overshot” type of gate, you were stuck with coding these gates using the weir/embankment button. While this is perfectly fine for steady state mode where you only have one weir height setting, it becomes problematic if you run the model in unsteady mode and the weir height changes during the simulation. Because you have to model the weir as part of the geometry, there is no easy way to adjust the weir height as a function of time in unsteady mode.

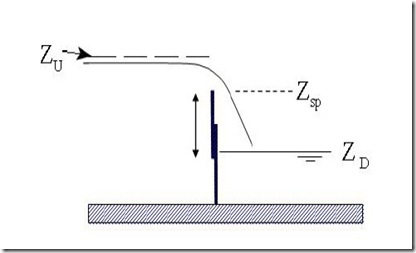

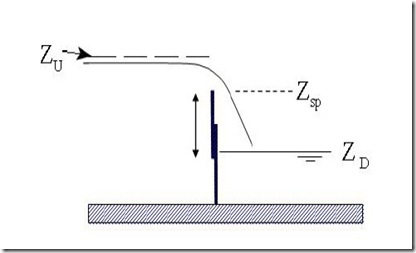

Starting with HEC-RAS version 4.0, there is a new type of gate called an “overflow gate.” As the name implies, this type of gate allows water to flow over the top of the gate as shown in the schematic below. There are two types of overflow gates in RAS: open air and closed top. Both of these gates allow water to flow over the top of the structure. The difference is that the closed top gate is kind of like an elevated orifice. At some water levels, water will flow over a closed top gate like a weir. At higher water levels, the closed top gate will function as an orifice.

For irrigation canals, open air overflow gates are exactly what we need to model overshot check structures. To use this option, enter the inline structure information exactly as before. Now, select “Overflow (open air)” as the gate type. There are three types of weir shape methods: Broad Crested, Sharp Crested, and Ogee. For modeling irrigation checks, using the Sharp Crested option is probably most appropriate. With this option, there are three ways to enter the discharge coefficient for the weir equation: User entered coefficient, Rehbock equation, or Kindsvarter-Carter equation.

The gate opening is still set through the flow editor (either steady state or unsteady state). For overflow gates, the gate opening is now from the top of the gate rather than the bottom. The figure below shows a check structure modeled with open air overflow gates. As can be seen, the gate opening on the far left is 1.56 feet. But this distance is measured from the top of the gate frame rather than the bottom. Now, if you are running this model in unsteady mode and the gate opening changes (that is, another weir board is added or removed), you can reflect this in the gate opening boundary condition.

Copyright © RASModel.com. 2011. All rights reserved.

In modeling irrigation canals in HEC-RAS, a typical structure that is encountered is a check gate. Check gates are designed to back the water up behind them in an effort to keep the water level immediately upstream of these gates at a constant level. As the flow rates change in the canal, the gate openings on the check gates are adjusted (i.e. opened or closed) in order to pass the new flow rate while maintaining the water level upstream of the check at the desired elevation. Why go through this effort? Farmers usually get their water from these irrigation canals via orifices just upstream of the check gates. The flow through these orifices is dependent on the head (or the water surface elevation) acting on it. Since farmers want a constant flow rate delivered to their fields, the check gates in the main canal are adjusted when the flow changes to make sure the water level upstream of the check (and hence the rate of flow delivered to the farmers) remains constant.

Check gates can take a wide variety of forms, but typically they fall into two categories: undershot gates and overshot gates. Undershot gates are things like radial gates and sluice gates. As the name implies, water shoots “under” these gates. Inline weirs are typical examples of overshot gates. For these structures, water does not pass “under” the gate but instead flows over the top of the structure. Since many irrigation districts operate on limited budgets, it’s not uncommon to see an overshot gate made simply of several 2x4 wood boards that slide into groves in the canal walls. The irrigation canal operator “opens” these types of gates by manually removing one or more of the wood boards. In a similar manner, these gates are “closed” by adding one or more wood boards.

Modeling undershot gates has been straightforward in HEC-RAS for many years. You simply select whether you have a radial gate or a sluice gate and then enter the appropriate input data for the gate. The gate openings are then set through the flow editor-either steady state or unsteady state-depending on your situation.

Modeling overshot gates in HEC-RAS has been a little more challenging. Unlike the undershot gates, there really wasn’t a gate type that allowed water to flow over the top like a weir. Thus, you had to model overshot check gates using the geometry of the inline structure. An example is shown in the figure below. The four long white rectangles in the middle of the structure are undershot types of gates (in this particular case, they happened to be sluice gates). The two short white rectangles at the far right and the two at the far left (the ones with the open top) are overshot gates. Because in previous version of HEC-RAS, there wasn’t a particular “overshot” type of gate, you were stuck with coding these gates using the weir/embankment button. While this is perfectly fine for steady state mode where you only have one weir height setting, it becomes problematic if you run the model in unsteady mode and the weir height changes during the simulation. Because you have to model the weir as part of the geometry, there is no easy way to adjust the weir height as a function of time in unsteady mode.

Starting with HEC-RAS version 4.0, there is a new type of gate called an “overflow gate.” As the name implies, this type of gate allows water to flow over the top of the gate as shown in the schematic below. There are two types of overflow gates in RAS: open air and closed top. Both of these gates allow water to flow over the top of the structure. The difference is that the closed top gate is kind of like an elevated orifice. At some water levels, water will flow over a closed top gate like a weir. At higher water levels, the closed top gate will function as an orifice.

For irrigation canals, open air overflow gates are exactly what we need to model overshot check structures. To use this option, enter the inline structure information exactly as before. Now, select “Overflow (open air)” as the gate type. There are three types of weir shape methods: Broad Crested, Sharp Crested, and Ogee. For modeling irrigation checks, using the Sharp Crested option is probably most appropriate. With this option, there are three ways to enter the discharge coefficient for the weir equation: User entered coefficient, Rehbock equation, or Kindsvarter-Carter equation.

The gate opening is still set through the flow editor (either steady state or unsteady state). For overflow gates, the gate opening is now from the top of the gate rather than the bottom. The figure below shows a check structure modeled with open air overflow gates. As can be seen, the gate opening on the far left is 1.56 feet. But this distance is measured from the top of the gate frame rather than the bottom. Now, if you are running this model in unsteady mode and the gate opening changes (that is, another weir board is added or removed), you can reflect this in the gate opening boundary condition.

Chris, Very Informative post here. Quick question on ogee weirs though.

ReplyDeleteI am using a sluice gate with an ogee inline structure. I have never worked directly with an ogee weir and HEC-RAS asks for inputs like "Spillway approach height", and "Design energy head". I am not quite sure what this is in reference too. Is there a post or reference manual somewhere that explains this more in depth?

Thanks for your posts as always!

The spillway approach height is measured from the bottom of the reservoir to the spillway crest just upstream of the spillway. The design energy head is not measureable, but comes from the spillway design calculations. It is theoretically the energy level above the spillway crest that the spillway was designed for. You can get more information about this from the Hydraulic Design Criteria manual put out by the Coastal and Hydraulics Laboratory from the Corps of Engineers' Engineering and Research Design Center (ERDC). http://chl.erdc.usace.army.mil/hdc

DeleteGood luck.

Hmm. Since I do not readily have the design specs for this dam to get the design energy head, could I just do a sensitivity analysis (low/high/mid) for the weir coefficient that those two parameters are used to calculate and go with the more conservative value?

ReplyDeleteI would imagine that an ogee weir is already efficient enough in my case that it would not have that much of an effect in the end.

Thanks for the link, very useful information again.

Sounds like a good idea.

ReplyDeleteChris, we have a model with these sorts of overshot gates, that run the entire length of a dam. We are modeling these gates as initially closed, and as a large hydrograph comes through the gates fail and are fully open. Then during the same hydrograph we are trying to model a breach of the inline structure. However, the results of the "with breach" case match the results of the "no breach" case exactly. It's as though RAS is treating the breach opening like it's not there, or that water cannot flow through it. Is this true for RAS, that it does not recognize a breach that is below an overshot gate? I ask because if we take the gate out and just pretend that they were open the whole time so that there is only the inline structure, the resulting hydrograph shows the impact of the breach. Thanks Chris.

ReplyDeleteCory- That is intriguing. I've never run into that before, but I can see how there might be some unintentional conflict in the code with breaching under a gate. Can you send me your model using the debug report (http://hecrasmodel.blogspot.com/2008/12/hec-ras-debug-report.html) and I'll see if I can see what is going on? Thanks-cgoodell@westconsultants.com

DeleteHi Chris,

DeleteI'm running into a similar problem - I can't model a dam breach through an overflow gate. Did you find a solution to this problem by any chance?

Thank you.

Hi chris, Thanks for your nice post. I have a question. I appreciate it if you can respond to me.

ReplyDeleteI was wondering why sometimes different kinds of gates( I mean overflow and underflow gates) is being used in the same check structures. I have seen many checks with five gates with 2 under flow gates on side and 3 overflow in middle. what is the purpose of such a design? Furthermore In time of operation do all gates open together or not?

Thanks for your time,

Mike

Mike, honestly I don't know the typical purposes of such gates. I have seen them used for fish passage, where the multiple outlet options give fish a preference for how they want to pass. Otherwise, not sure...

DeleteHi, I am a relatively new user. I am confused about a simple thing. I want to model a overflow structure with around 15 gate openings. Do I need to draw a solid embankment extending from the starting to the ending of the gates using the weir/embankment option under inline structure before defining the gates? Or do I need to keep opening in the embankment?

ReplyDeleteYes to the first question. Draw your embankment first, then put in your gates.

DeleteThanks Chris for the informative post.

ReplyDeleteI like to model radial gates and sluice gates with broad crested weir. Is it possible to use broad crested weir with radial gates. Even though in the selection dialogue box it is there, I doubt that, as all the explanations related with radial gates are drawn with ogee spillway.

Yes, you can definitely do that.

DeleteHi chris,

ReplyDeleteI have a question about external data interface for canal automation (EDI). i wanted to know if the project was success full and could simulate the real canal system.

I have seen in some articles that using saint venant equations is too complicated for canal automation purposes and needs lots of data. Instead the suggest to use industrial control system approach. Furthermore, in a book which has been published by ASCE http://www.asce.org/templates/publications-book-detail.aspx?id=6965, they suggest that to use similar approaches. I want to know your opinion .

Cheers,

Mike

Hi Mike,

ReplyDeleteChris asked me to reply to your question. In reading your question, I wanted to clarify something first. As you point out, it is true that using the St Venant equations to design a controller is not a good idea because of the non-linearity of those equations. Thus, controllers are typically designed using some sort of linearized approximations of the system (i.e., industrial control system approach).

However, when testing the performance of a designed controller, it is no problem to test them via simulations using the full St. Venant equations using unsteady HEC-RAS. In fact, you want to do that to make sure that the controller (designed using simplified approximations) will behave as expected in the real nonlinear world.

The EDI program that you are referring to did work successfully. We were able to model the unsteady hydraulics of the canal successfully and had calibration data to verify the model performance. In the particular project that we used the EDI, we did not actually design controllers and test controllers as that was not the goal of the project. Instead, we used the EDI as an interface between the HEC-RAS model of the canal and the SCADA system used to monitor and control the canal.

Does this answer your question?\

Thanks.

Brian

hanks Brian for your response. I have some questions, I appreciate that if you could answer to me. Please let me know if you think that it is better to contact you by email.

Delete1- I was wondering if there is any publication available for the methodology which has been implemented in this project.

2- How did you calibrate the model?

3-Did you calibrate the pools one by one or calibrated couple of pools together?

4-How did you model turns out in Hecras ? you did n't have instability issues in the turn outs?

5-Can Hecras model water levels with +/- 5 centimeter accuracy in irrigation canals?

6-what parameters did you put from designed controller in Hecras?

7-It is possible to use such approach for earthen canals? Do I need to re calibrate the model after couple of years due to sediment and weeds?

8- Do you have any instability issues due to sudden opening/closing of the gates?

9- Have u built any physical model in lab for irrigation canal and make a same Hecras model and compare the results?

10-Is it possible to use Hecras to model sediment transport in irrigation canals? Is this model reliable?

Sorry if I asked too many questions.

Hi Chris, thanks for pointing out this option! One thing is not clear to my however: How can I control the gate's Crest Level (as opposed to the Gate Opening Height)? Is the only way to do this by implementing a closed top overflow gate and applying negative opening heights to it so as to keep the gates closed at all times and only allow for flowing over the gate's top? Or is there an option using an Open Air gate as well? As far as I can tell the Unsteady Data Editor only provides a possibility to enter a timeseries for the Gate Opening Height; not for the Gate Crest Level.

ReplyDeleteSiebe, with overflow gates, the gate opening value you enter in the unsteady boundary condition is measured from the maximum gate top elevation (gate fully up) to the actual gate top elevation. For example, you set the Height in the overflow gate geometry properties to 4 meters. And the gate invert elevation is 0 meters. If you put in a gate opening height of 1 meter in the unsteady flow boundary condition table, the gate will be open so that the crest of the gate is at elevation 3 meters.

DeleteThanks Chris! It's rather embarrassing how long it took me to understand the concept :"(. In The Netherlands we simple don't have any gates that move downwards in order to open up. All of our gates are opened by pulling them up, so it took a little mind bending to understand it.

Delete:) Totally understand. Glad you got it!

DeleteHi Chris,

DeleteI am sorry to bug you but I scaned through the Ras Solution forum but I could find anything related to my question

I have to model a flood gate like those I have attached (https://www.google.com/search?q=floodgate+lock&tbm=isch&tbo=u&source=univ&sa=X&ved=0ahUKEwjHnsTOoZPUAhVMSiYKHcqZAZkQsAQIIw&biw=1920&bih=950#imgrc=Inqy4k5wL_bwHM:). The operations is easy. The gates are closed when we are expecting a tidal wave but are normally opened. In terms of hydraulic performance of the gate when they are opened, which of the available options in Hec-ras should I choose. Right now I have modelling it as a sluice gate that is opened. Or how else can one model a floodgate like that that opens like a double door.

Thanks

Ebai

Since RAS doesn't have a double door type gate built in, you have to do some sort of workaround. If you can accept a little bit of error during the opening/closing sequence, you could just pick one of the available gates and try to make it work that way. This might be okay if the gate opens/closes relatively quickly. Or, you could develop your own rating curve and model the gate with user-defined curves. The problem with this is that user-defined curves are tailwater independant, and based on your description and photos, that is not the case for your gate. That leaves you with writing rule scripts. It's sort of complicated, but you could develop rating curve tables for a range of tailwaters, and use rules to pick from the correct table, based on the computed tailwater. That's probably what I would do if I needed it to be super accurate. Otherwise, I'd probably just go with one of the built-in gates available in RAS.

DeleteHi Chris,

ReplyDeleteWe are facing a problem while modeling a simple irrigation concrete canal with less than 10 sections. After adding some section or do some minor changes in the model, it was stuck at the first stage of writing geometry information and we could do nothing but close it and go back to the original one which could run successfully.

I am wondering is it a problem with canal sizing that is decreased with the distance that brings the model instability.

Jane (Thailand)

That shouldn't cause problems. It is likely that whatever you are adding/changing in the geometry is causing some kind of problem with preprocessing. Double check the data entry and make sure there are no errors. Also, make sure you are using the most updated version of HEC-RAS-version 5.0.3.

Deletesir i am not getting that which height is called as invert height/level of gate. radial gate discharge coefficient and trunnion height of gate please help me out

ReplyDeleteThe manual discusses this in good detail, but if it doesn't cover it enough, check out the reference it uses for radial gates.

Delete